Ask any architect who has developed a set of construction documents to describe “what constitutes a thorough set of construction documents and what is the process used to develop construction documents,” and you will get as many varied opinions as the number of architects you ask. Expand the discussion to include developing construction documents for use in other countries that are not the architect’s home base of operations, and many additional comments and observations will come to the fore.

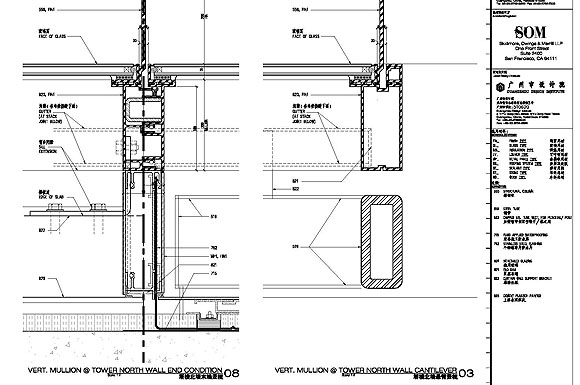

Construction in China is booming. The San Francisco office of Skidmore, Owings & Merrill LLP has been very active in design, documentation, and construction-phase services in China since the early 1990s, working with Local Design Institutes (LDIs) to develop construction documents that integrate local practice and incorporate international standards of construction quality. We entered the Chinese market early on, starting our first significant project, the Industrial and Commercial Bank of China’s (ICBC) Beijing headquarters, in 1994. ICBC’s design required details for several systems, such as steel-frame construction, custom curtain wall, and custom stonework, which were fairly rare in China at that time. The project’s success established an important precedent for SOM’s subsequent commissions throughout China. The more recent rapid growth of China’s economy, the country’s desire to advance its own design and construction capabilities, SOM’s expertise in large-scale project execution, and our desire to achieve the highest level of design and construction set the stage for a remarkable period of advancement.

The process of developing construction documents in China has been, and continues to be, a learning experience. Our approach has evolved significantly over the last decade, reflecting the tremendous amount of change and advancement we have witnessed on both sides of the table. Our knowledge of local practices and relationships with local institutes and fabricators has expanded with each project, allowing us to anticipate issues and propose new approaches to collaboration with the local Chinese design and construction industry. To fully understand the challenges and possibilities, it is helpful to compare the approaches to and philosophies about construction documents in China and the United States.

What Are Construction Documents in China?

This seems like a simple question, or it did to me when I started this effort, but as with most issues the answer has evolved over time. With ICBC, our first full-service project in Beijing, the client’s design brief requested “an international quality project that would be respected worldwide.” For this discussion, full services meant design, documentation in all phases, and involvement in the construction phase of the project. At the same time, the client, recognizing the opportunity for knowledge transfer, stipulated that local builders and fabricators should be involved to the highest degree possible.

Acknowledging the physical distance between our office and the project—a time difference of sixteen hours—the unknowns of local manufacturing capabilities and fabricators, and the language difference, our first step was to place key team members on the ground for several weeks to gain a basic understanding of the capabilities of the local design and construction industry and the existing local standards and rules of engagement. We knew from working in other countries that if you are going to play in someone else’s yard and succeed, you had better know the local rules of the game. Our reviews and interviews included visiting local construction sites, meeting with the client to reach a mutual understanding of the definition of “international quality,” interviewing Local Design Institutes, and gathering information on manufacturing capabilities of architectural building products and systems. We realized early on that our investigation had a parallel track with project team members in China, who were trying to understand our process. Some significant findings resulted from this early review. One of the most memorable was the review of examples of construction documents for recently completed projects prepared by the LDIs. Floor plans, building elevations, and sections were comparable to a set of design development drawings prepared for projects in the United States. Drawings for detailed items such as doors, exterior enclosures (curtain walls, windows, stone, etc.), partitions, and interior finishes exhibited very little or no detail and were largely left to the local builder. The building systems for these items consisted of “stock” materials and systems selected from manufacturers’ brochures.

The client’s objective of “international quality” set a level of material and system quality, which at the time required importing a high quantity of materials. The construction documents were required to define materials and assemblies, establish quality standards using U.S., European, or Japanese standards, and define the method of installation that could be performed by the local workforce with some or no formal training in these trades.

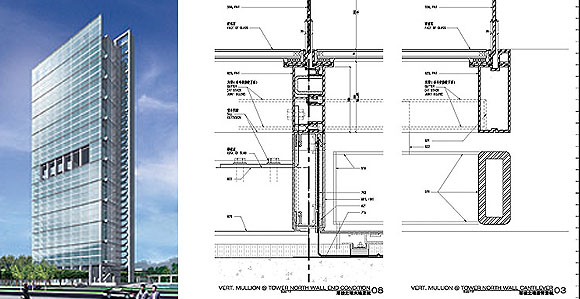

The majority of the construction documents and specifications were prepared by SOM in the San Francisco office, incorporating English and Mandarin text. The common ground between the English and Mandarin text was a numerical indicator for each note. To aid in drawing legibility, a master notation system incorporating each language with the numerical notation was developed for each material or assembly. The notation system was included on each sheet to facilitate use of full or partial drawing sets by SOM, the LDI, and international fabricators and contractors. The completed set of construction documents was structured in a similar fashion to a set of documents we would prepare in the U.S., with the addition of the numerical notations for bilingual use.

A thorough and well-coordinated set of construction documents is one of the key factors of a successful project. However, if the documents’ authors are not actively involved during construction, interpretation of the design and detail intent for both typical and atypical conditions is at best a roll of the dice. To assist the local and international contractor team, we contacted international fabricators and contractors of curtain wall, specialty metal fabrications, and stonework that we knew possessed the ability to deliver the more custom aspects of the design in a locale where this type of work had not been performed before. In addition to the recruitment of selected fabricators, we placed several of our team members on site for extended durations to work hand-in-hand with the LDI and local construction trades to guide and offer assistance in the work. We recognized that the opportunity for this type of in-depth involvement is more the exception than the norm. Local owners and companies were impressed with the results of the project, but noted that while they were also interested in a quality project, it was not financially viable to enlist a U.S.-based architect to provide full scope of services and to import a high quantity of building materials, systems, and expertise. To be financially competitive and still achieve an edge in design and building technology required a balance of involvement with the LDI, local building industries, and the U.S-based design team.

Ultimately, the fundamental considerations and level of detail documentation for construction documents are not significantly different in China. Each project design sets forward materials and systems that will result in either “manufacturer’s standard” systems, materials, and details, “customizing a manufacturers’ standard,” or “custom” detailing. Similar to practice in U.S. cities, there are national and local regulations that vary by city. The construction document sets are tailored to the specific requirements of each project. The answer to the question of “what are construction documents,” therefore, is directly linked to the question of “who does what.”

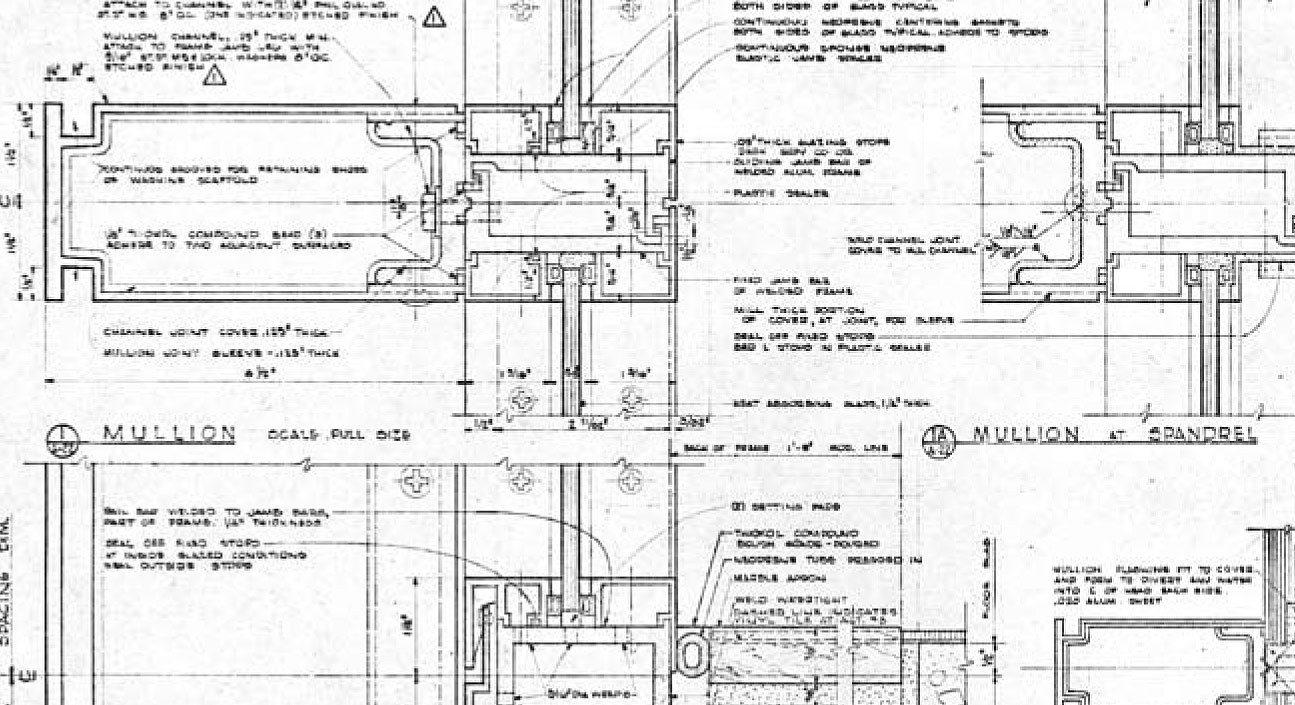

The image below is a curtain wall detail from the Poly Guangzhou Complex, a current SOM project in Guangzhou, China. It is compared here with a curtain wall detail from the firm’s Crown Zellerbach Building in San Francisco of 1959, above, to suggest a notable difference between details of the two periods. Because curtain wall construction was a novelty at the time of Crown Zellerbach, the architects drew every detail and specified every material; the drawing was about describing the curtain wall element itself. In current practice, the emphasis is instead on describing the relationships between manufactured curtain wall elements and the the other building systems. Drawings courtesy of Skidmore, Owings & Merrill LLP.

Who Does What in China?

The basic answer to this is whoever is the most qualified of the U.S. or China design team members to perform the detailing of specific portions of the documents. There are many local jurisdictional requirements regarding which the LDI is more knowledgeable. In cases where the engineering disciplines (structural, mechanical, electrical, etc.) are local, the coordination effort between the architecture and engineering teams puts a heavier work emphasis on the LDI, and the converse is true in projects with more U.S. consultants. Highly customized details that are critical to the success of the design—exterior enclosure, public spaces, and specialized uses or systems, for example—are developed and detailed by SOM.

The construction documents for these areas include both drawings and specifications. The custom details are developed to illustrate size, profile, and type of materials, as well as interface with adjacent materials or systems. The specifications include a combination of local materials and internationally available products. We include local products or fabricators only after a thorough review and screening process for that particular material or system. The construction documents for floor plans, reflected ceiling plans, and other overall layout drawings is a shared effort. We develop these drawings during the schematic and design development phases, and usually the LDI takes them through construction documents phase with reviews by us at key milestone dates in the construction document process.

Where Are the Construction Documents Prepared?

In a shared documentation effort, the lead firm, SOM or LDI, prepares the documents in each home office and exchanges and shares at deliverable milestones for review. To develop drawings concurrently at separate locations requires careful delineation of responsibilities in the early planning stages of the project. In addition to face-to-face coordination sessions between the architect and engineering disciplines, the LDI and SOM hold regular coordination sessions, typically in the city where the project occurs. Even in the age of computer file transfers, face-to-face working and coordination sessions are essential for team members to fully understand the necessary drawing content.

When Are the Construction Documents Prepared? When Are They Finished?

Usually the most difficult question to answer is, “When are construction documents complete?” Those who have developed a set of construction documents know that there never seems to be enough time to fully detail the project. The pace of construction in China is much faster than in the U.S. On recent projects we have developed details for the customized areas in a staged sequence that generally follows the stages of construction. To accommodate the accelerated pace of construction, we have prepared some of the more custom details that apply to large areas of the project by the end of the design development phase. Construction documents have been prepared in distinct trade packages such as exterior enclosure, public spaces, elevator/escalator system details, and special use areas. For larger- scale projects, these construction document trade packages are further divided into distinct packages for (for example) exterior enclosure for the building base, for typical floors, and for the top.

Why Does a U.S. Firm Prepare CDs in China?

The projects we have completed and are currently working on are complex buildings with custom-designed systems and details in select areas that support and enhance the design. To facilitate a finished product that meets the original design intent to the greatest degree possible and to achieve the necessary quality level, the author of the design must be the author of the details. Additionally, we have developed expertise in several areas that do not currently exist with LDIs.

On the other hand, the LDIs possess specific local knowledge, expertise, and capabilities in areas that U.S. architects do not. There are many similarities in this international collaborative approach to situations when two architects are teamed together on domestic projects. Beyond the delineation of who does what the heart of the issue is developing a working collaborative in which there is mutual respect. The basics of clear and constant communication, buildability, and clarity of document information must be monitored from the inception of the design intent to final completion of the documents and occupant move-in.

Author C. Keith Boswell, AIA, is a technical partner of Skidmore, Owings & Merrill LLP. Based in the firm’s San Francisco office, he oversees the integration of design vision and building technology across a broad array of building types located worldwide.

Originally published 1st quarter 2006 in arcCA 06.1, “Imbedded Knowledge.”