Global climate change and widespread shortages of basic resources today make the adoption of more sustainable building practices imperative. Yet the mechanical, electrical, and plumbing engineers who are often in the best position to reduce energy and water use in buildings are, paradoxically, often the most resistant to changing deeply ingrained, inefficient design practices.

As public demand for green buildings grows and they become increasingly crucial to our social and economic health and stability, design professionals must work to remove cultural barriers to the rapid adoption of sustainable building practices. It’s not as much about new technology as it is about changing perceptions and behavior. In general, architects have been more receptive to sustainability—it’s time for engineers to follow suit.

What architects say about engineers

Here’s a sampling of the comments I’ve heard about engineers from architects: “Don’t engineers know anything about green design?” “Why are the engineers knocking down all of the green strategies?” “Can’t we get more energy points?” “Engineers want to design thermos bottles with no windows.” “I hate working with engineers!” Is there such a thing as a “green engineer”—or is this an oxymoron?

Much of this professional disconnect stems from differences in how architects and engineers are educated. Engineers are trained to accept “givens” and “rules of thumb.” Our learning focuses on absolutes like Q = U A ΔT; the Second Law of Thermodynamics (Entropy Increases); heat flow through insulated pipes and walls; fluid dynamics; heat transfer, and turbomachinery. We’re typically focused on system performance—that’s why we’ll often “default” to whatever worked on the last project.

Architects, by contrast, have a broader education, and are much more likely to be exposed to sustainability through ideas such as sun angles; building orientation, environmental context, “organic” architecture, and the impact of buildings on society. Architects are rewarded for dramatic new ideas in buildings, which are visually apparent, although much harder to measure quantitatively than mechanical systems performance. Also, they have the benefit of a more holistic perspective by virtue of their traditional role as project managers coordinating a wide array of trades and disciplines.

Incentives and innovation

Architects and engineers have entirely different incentives for innovation. Basically, architects are encouraged to innovate and are rewarded for new designs. Engineers, on the other hand, are trained to avoid risks. There’s no real reward for innovation: if systems are underdesigned, buildings are uncomfortable or even dangerous. If they’re overdesigned, no one notices. The best defense for engineers in a lawsuit is that a given design follows “standard practice.” Under tight budgets and fast timelines, conservative Rules of Thumb are used in design. Innovative design takes more time to do, and there’s considerably more resistance to doing it. Adding to this is the fact that we’re also incentivized on the equipment side. Ideally, we should be trying to engineer out or downsize mechanical equipment, but if we follow the trade practice of tying fees to a percentage of construction costs, the more equipment we install, the higher our fees are.

Other factors influence the current design practice paradigm of mediocre performance. Architects are usually our clients, and we’re often reluctant to push hard or ask them to change their design. Also, key design decisions that impact energy are often already made before the engineer is brought in. Then, after the building is built, engineers get blamed for occupants’ weird behavior, such as leaving windows open in winter, breaking thermostats, setting them to 60 degrees, or complaining about 72 degree room temperature.

The result of this state of affairs is dramatic, architecturally innovative buildings with mediocre energy performance and user comfort.

What happens when engineers don’t get it?

The engineer’s traditional way of approaching energy savings is to look at building components separately, such as insulation or windows, calculate the simple payback and energy savings, add more insulation or better windows, and stop when they hit the client’s payback comfort level. What are we forgetting in this scenario? We need to be looking at the bigger picture, seeing the building as a whole system—architects are usually better at this. Changing one part of the system can have significant impacts on every other part and eventually create a very different set of economics. More insulation and better windows, for instance, also can create an opportunity to reduce the size of the heating and cooling systems and ducts, as well as saving energy. Optimizing fenestration saves energy by presenting opportunities for using daylight instead of electric light.

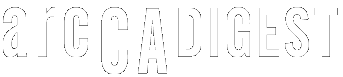

In the culture of engineering, “Cookie Cutter” design is enshrined. We frequently design too quickly, with big fat safety factors and no thought for total system optimization. When estimating loads, many engineers use “rule of thumb” tables that haven’t changed for more than a generation, and bear no relationship to local climate conditions. Even building codes encourage overdesign. Studies have shown that the transformers in an average building are only loaded at about 20% of capacity. Much of this is related to code required lead calculations. Because it’s so hard to swim against the current, we often feel defeated—we’ve lost the existential pleasure of elegant engineering solutions inherent in the most efficient designs.

Wasteful and inefficient design is embedded in engineering trade practice today, on a huge scale. Engineers design for worst-case-scenario extremes, not for typical conditions. This can result in sacrificing not only energy savings, but comfort. We typically hate operable windows, following the received wisdom that we need to positively pressurize buildings, so that air leaks out, not in. What if someone opens a window on a hot day? Humans’ irrational and unpredictable behavior doesn’t factor into our calculations.

What needs to change so that engineers can begin to design more sustainably? As much as we are prone to technological solutions to many of our problems, technology is only a part of the answer. Good technology, in the form of new materials, systems, and equipment, is already available and has been for some time. I think there are three main parts to the solution: design collaboration, economics, and aesthetic models.

Better design collaboration between all members of the team—architects, owners, user groups, as well as the engineers, can be seen as a positive evolution in our industry, and is being driven by a number of factors, including increasingly sophisticated design software and rapidly escalating construction costs. Engineers need to adapt to this trend.

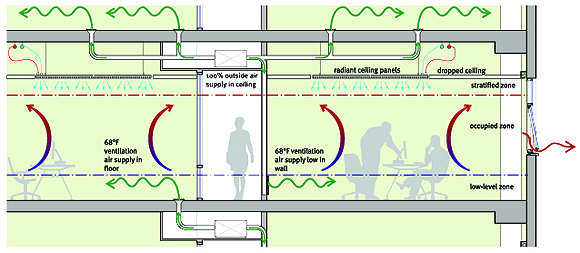

We also need to develop better design communication tools—in my office, schematic diagrams are developing into a fairly extensive “vocabulary,” as we focus on creating visualizations that clearly explain our systems to technical and non-technical people alike.

On the economic side, I like to cite what my friend and colleague Amory Lovins refers to as “Tunneling through the Cost Barrier.” This means going beyond simple paybacks on a part of the system, and capturing efficiencies based on the whole system. It’s almost counterintuitive, but with the right design approach, it’s really possible to capture big savings at little or no extra cost. We really need to do this today, given our climate and energy situation.

One of the most dramatic differences between architects and engineers is that architects are highly focused on visual aesthetics, while the aesthetics that drive engineers concern things that are less visible. Aesthetics are a key part of how we behave as designers, and there is usually a practical side to them – most of us still believe that form follows function. Aesthetics can drive inefficient, energy intensive design; why not have them drive sustainable design instead? Many of the best architects in the recent past had an intuitive understanding of what we now call “sustainability” long before green was hip. In fact, traditional building practices all over the world are rich in “sustainable” concepts that evolved over millennia, long before mechanical equipment was used to mitigate the heating, ventilating, and cooling problems created by glass and steel high-rise technology. We need to create and promote a new aesthetic model of sustainability: we know that end users love the look and feel of truly sustainable buildings.

Recovering the existential pleasure of engineering

Not that long ago in our history, engineers were heroes. We were the driving force behind the Industrial Revolution and all the ensuing technological development that has so utterly transformed our world. Somewhere along the line, probably around the 1960s, we became the focus of a public backlash against technology, and we withdrew into professional insularity and stopped innovating.

Fortunately, one of the saving graces of our profession is that inefficiency is irrational from an engineer’s perspective: when faced with a half empty glass, we’re inclined to think that the glass is too big, rather than half full. There is indeed a great pleasure in creating elegant engineering solutions that celebrate efficiency, and we need to recover this joy in our work and share it more openly. Engineers will be the ones who come up with the solutions to our climate and energy crisis, and as we all know, the stakes are huge. Consider this:

Building systems last, on average, for 30 years. The average architect or engineer will design something like 10,000,000 square feet of buildings in his or her career. If these buildings are designed to be highly energy efficient (with 50% energy savings), the difference this can make for a single designer over a lifetime career is roughly equal to the energy produced by 3,700 large-scale wind turbines, or more than enough to power a city the size of Portland for an entire year.

Author Peter Rumsey, PE, President of Rumsey Engineers in Oakland, California, is widely recognized as a global player in energy efficiency and a leader in sustainable building design. Peter and Rumsey Engineers have been responsible for many key innovations in energy efficient design and analysis. Peter is an ASHRAE Fellow, a Senior Fellow of the Rocky Mountain Institute, and a recipient of the 2005 AIACC Allied Professions Honor Award.

Originally published 3rd quarter 2008, in arcCA 08.3, “Engineering + Architecture.”