The resistance to building information technology that I’ve heard reminds me of a survey of architects using computers in 1988, Computers in Australian Architectural Practice, by Antony D. Radford. There’s a nice introduction that is still apropos today. The author starts, “Why write a book on computers in architectural practice? There are no books devoted to drawing boards in practice or typewriters in practice or filing cabinets in practice, yet computers overlap all these things… Because they can affect so much in architectural practice and because they imply new and different ways of working, it is worth sharing the experience of how best to use the technology.”

Along with the rest of the business world, architecture practices have adopted computer technology. And on the way we’ve converted drawing boards into 2D CAD drawings and delivered them as PDFs. But unlike other comparable industries, such as banking or manufacturing, we haven’t materially changed work practices; we are still using work concepts from 1900. So far, we haven’t considered what computing really means and how we should use it.

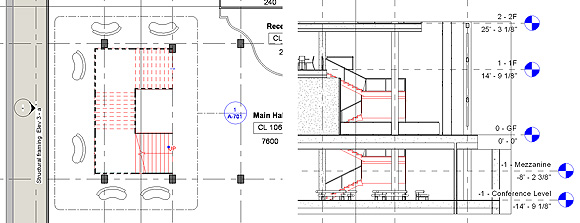

So is this a revolution coming? You bet! This is the real change in the industry. Instead of taking whatever vendors sell us, we make a conscious choice—indeed, we do what we tell our clients to do: we plan, not only as individuals, but as an industry. The technology at hand is building information modeling (BIM), an integrated model of a building that does not consist of the independent lines and arcs of drawings, but of objects, accurate in 3D, described by properties, and related to their surroundings. These models can be visualized, audited, analyzed, priced, and automated. Choosing BIM, however, is just one of our planning tasks. Another decision is whether we tackle the problem of sharing information known as “interoperability,” revealed in all its embarrassing detail by a study by the National Institute of Standards and Technology—and ignored by most as too hard to achieve.

But it isn’t too hard, for the issue is whether the industry decides on its own information standard and its own future or lies back, whines, and complains about clients and builders and fees. We need a standard that supports the activities and needs of one of the most complicated sets of processes of any human endeavor: designing, constructing, and operating buildings. Every other industry has such a standard. When you travel overseas, you expect to be able to get money anywhere, enabled by a global standard for financial transactions. Yet you’ll probably put this article down and go off to a meeting where the project team has discovered yet another error on the construction site causing delays and extra costs. Shouldn’t that situation be changed?

The biggest single issue is the development of industry standards. The best analogy is the emergence of railways in the nineteenth century. Until the government in Britain decided upon a standard gauge, a multitude of train companies had their own railway systems—working in their own area (FEM), specialized for some task (DWG), with wide tracks (XML), narrow tracks (HTML), light loads (VRML), heavy loads (TIFF), etc. When the standard gauge was agreed upon (when industry and government made a strategic decision for the benefit of all), train companies found they could connect (interoperate), and an astounding increase in commerce occurred. Some companies disappeared, some people lost money. Travelers embarked on a transportation revolution. That’s what we need for the built environment now.

The International Alliance for Interoperability (IAI), a global partnership of construction industry organizations, has developed such a standard for the construction industry. The industry foundation classes (IFCs) are an ISO standard that allows building information models to be shared among the multitude of participants in the development process and over the life cycle of a building. Any application that supports IFC can share data— between architect and thermal engineer, contractor and steel manufacturer, contractor and facility manager, and design team and client. Building information modeling will replace drawings as the definitive source of building information. It has not only automated drawing production, an essential prerequisite since drawings are far too useful to ever disappear, but also, more importantly, enabled simulation and performance measurement. We can get a more accurate thermal load. We can develop options faster. We can actually spend more time on design optimization than when we had to have a team of our expensive staff obsessed by drawing lines (or have a quantity surveyor measuring lines). From this same model we can now calculate embodied energy. With the client, we can calculate life-cycle cost. With the contractor, we can really test constructability.

You’re skeptical? Your vendor tells you it’s impossible, too early, not feasible? Wrong. That vendor wants his obsolete 2D CAD or his non-interoperable 3D products to continue on the market. Too late! The technology has arrived and has been definitively shown to work. Look at the website for the Nordic Chapter of the IAI and see the presentations given at the chapter’s industry day in May, 2005. Sixteen software vendors demonstrated in-sequence importing, value-adding, and checking a common IFC model. It works. (A cheeky games vendor and the innovative captain of the Oslo Fire Brigade took that same model data and simulated burning the building down). Norway’s building agency also demonstrated the Byggsøk Planning Approval system, using IFC models and integrating GIS data from planning authorities and other government utilities.

And it would work even better if you and your consultant partners evaluated and tested this concept. Take a cool look at your business and where it wants to go in the next ten years. Do you want to be an architect of a decelerating drawing commodity business? Integrated practice is essential. Look at the leaders of the professions and what distinguishes them—the way they collaborate, examine problems from every angle, and squeeze out every last drop of innovation. To do that, you must have every piece of information at your fingertips and be able to analyze and manipulate that data. Collaboration depends on the open and rich data that IFC provides—not a proprietary or private data environment, and not a set of products called myCad, myStructure, myMechanical because they only talk to themselves rather than to the industry.

This is not just a problem for architects, of course. Yet, my experience is that the problem is laid at their feet when the subject is discussed in industry forums. Why? Because the architect is the person trained and skilled in managing information (or designing, if you prefer to call it that). Architects have an unparalleled opportunity to reestablish themselves in the design and construction process. But they have to lead!

It means working with the industry to decide upon a common environment for building information and proactively adopting a technology—BIM—that is manifestly a better way to manage our processes.

It means making some hard decisions and looking out globally at what’s happening elsewhere, such as Scandinavian countries, where Finland and Norway have established a big lead.

It means understanding the GSA directive for what it is: a big step toward changing the U.S. construction sector to be able to exploit IT for the benefit of construction (instead of sales for suppliers) and to achieve better value and a better performing building stock.

It means developing a technology strategy and plan for your company that articulates the business objectives first and then selects providers and vendors that support you, not sidetrack you.

It means addressing the serious social issues of energy consumption, environmental quality, productivity, reliability, sustainability, innovation, and that nebulous concept, design. Isn’t that what an architect signs up for?

Author John Mitchell is a consulting architect working in Sydney, Australia. He teaches collaborative design using BIM at the University of New South Wales and is the chairman of the IAI-Australasia Chapter. This article was previously published in volume 02/2005 of _line, AIA San Francisco’s online journal, www.linemag.org; reprinted with permission of the author and AIASF.

Originally published 1st quarter 2006 in arcCA 06.1, “Imbedded Knowledge.”